MARKING

Markings are usually produced through an electrochemical etching procedure. The smooth surface of the material remains the same during this process.

MICRO-BLASTED ENDS

Micro-blasted areas are used for a better glue joint with plastic components. Micro-blasted areas on the needle point are used as echo sound markings for ultrasonic examination.

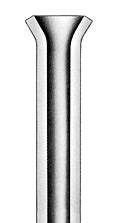

FLARED ENDS

Flared ends guarantee secure embedding in plastic components in the axial direction.. The flared end diameter is determined by the ratio of tube OD and wall thickness.

REDUCED ENDS

Reduced ends are used for several products and may lower the penetration force with cannulae. Please note that wall thickness may be affected in the reduced area.

PRECISION MACHINED BORES

If fragmentation-free piercing of membranes for injection or aspiration is required machined bores are suitable in connection with closed needle points.

LATERAL DRILLED BORES

If exact dosing is required for injection or aspiration drilled bores are suitable.

KNURLED

Knurled tubes guarantee secure embedding in plastic components.

A. Steel material:

304, 304L, 316, 316L, etc.

B. Tube dimensions:

OD and ID of tube or reference either OD or ID with wall thickness

Custom tubing sizes are always available, however the use of standard tubing gauge and tolerances, per our charts, U.S. Industry Standard Medical Grade Stainless Steel Tubing Dimensions, and ISO Standard Tubing, will result in quicker turnaround time.

C. Tube Surface Finish:

If your application requires this, please request either a mirror finish ID or chemically polished OD. Both add cost but may increase the functionality of your device. Our standard tubing is very smooth both inside and outside so that add-on surface treatments are usually not required.

D. Tube Hardness:

Request a range in Vickers if your application requires. If not referenced, standard tubing is ¾ - full hard.

E. Tube Surface Roughness:

ISPG uses roughness average (Ra) per micro inch or micron to measure the surface roughness of cannula.

F. Overall Length (OAL):

Request the tolerance you need. Typical OAL tolerances are +/- 0.020" (+/- 0.5mm), but tighter tolerances are not a problem.

G. Heel-to-Butt Length:

On cannulae, you may prefer to reference this dimension rather than OAL.

H. Bevel Length:

Reference the overall bevel length if required.

I. Notches or Holes:

If required, reference notch length and depth and hole width. If any radius is required, please specify. Reference hole/notch position from the butt end.

J. Butt End Treatments:

Reference chamfer or a radius if required for your application. Parts without a specific butt end treatment referenced are produced square-cut and deburred.

Are you looking for a supplier that can make a customized cannula or needle as your design or sample? Here is your platform to make it true!

Question 1: What kind of cannula can you make?

Answer: We can make many kinds of custom cannula as your drawing or samples.

Question 2: What's the material?

Answer: Usually we use medical grade stainless steel 304, please let me know if you want other material for your customized cannula.

Question 3: Can you make samples before order?

Answer: Yes, we can make samples for your confirmation.

Question 4: What's the MOQ?

Answer: It depends on your cannula.